AISC President Charlie Carter writes on the sustainability of Structural Steel in The Morning Call Op-Ed

American steel is more sustainable than ever

By Charles Carter

March 25, 2024

The Morning Call

A groundbreaking new research center showcasing a sleek, cutting-edge design will soon rise at the University of Pennsylvania, constructed with what is arguably the most sustainable building material available today: American steel.

Even though I graduated from Penn State with a degree in architectural engineering, when it comes to championing sustainable construction, such rivalries take a back seat to our shared goal of building a stronger Pennsylvania.

To many Pennsylvanians, the notion of “green steel” may come as a surprise. In recent years, American steel has been unfairly maligned by special interest groups who cling to an outdated portrayal of the industry as “dirty” and “inefficient.”

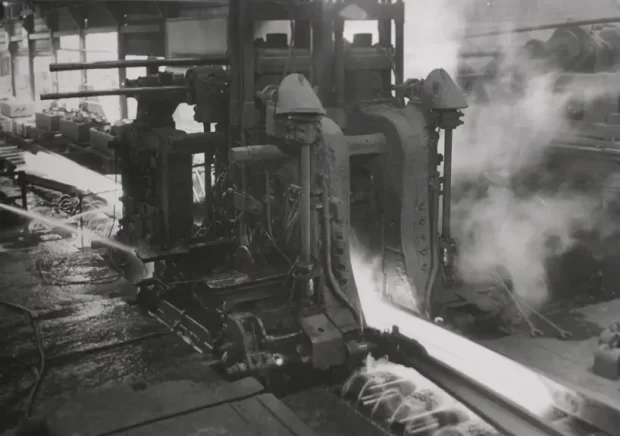

This biased portrayal could not be further from the truth — American structural steel today stands as the pinnacle of sustainable construction materials. The U.S. steel industry has shed its image as a relic of smokestack industrialism, propelled into the forefront of clean manufacturing and production efficiency by new technology. As the sector continues to embrace new technologies and the power grid becomes increasingly green, the long-term sustainability of steel will only increase, positioning it as the top material of choice for eco-conscious architects and engineers.

The industry has undergone significant transformations, committing to sustainability and making U.S. steel the greenest on the global stage, according to a study by consulting firm Global Efficiency Intelligence. Where competitors in China and Europe still rely on coal-fired generating plants or traditional basic oxygen furnaces to turn coal, coke, and iron ore into steel, America’s leading structural steel producers have adopted electric arc furnaces. These modern facilities use recycled steel and renewable electricity, setting a new standard in clean production.

Despite these advancements, proponents of alternative building materials like timber continue to challenge steel’s environmental credentials. Such comparisons often disregard the inherently circular nature of steel production, making it the ideal sustainable building material.

In the United States, structural steel elements — such as the wide-flange beams and columns regularly seen on construction sites — are comprised, on average, of 93% recycled material. Moreover, steel is the only construction material that is 100% recyclable, maintaining its properties indefinitely through cycles of reuse, unlike concrete and wood, which frequently end up downcycled, incinerated or in landfills.

The American structural steel industry is no longer powered by coal; rather, it relies on electricity to melt scrap into new steel shapes. And as America’s electricity generation transitions to renewable sources, steel’s carbon footprint continues to drop. Over the last five years, according to our calculations, the leading U.S. steel mills have reduced their embodied carbon by almost 15%.

As the demand for steel increases, the industry’s response has been proactive, with new production facilities and investments in wind farms and solar fields, all of which help to create jobs, contribute to the revitalization of communities, and underscore the industry’s commitment to a sustainable future.

Pennsylvania stands on the brink of this future, epitomized by the newest building on the University of Pennsylvania’s campus in Philadelhia, the Vagelos Laboratory for Energy Science and Technology. The building, a beacon of sustainable energy research, demonstrates the synergy of American steel with innovative engineering and forward-thinking architecture. Its versatile design and construction reflect the building’s mission: to advance the study of sustainable energy solutions. The choice of steel underscores the critical role of a revitalized U.S. manufacturing sector in achieving this goal.

American steel is driving the revival of American cities, offering a blueprint for clean, efficient, sustainable construction unmatched by other major steel-producing nations. However, the benefits are not measured in beams and columns alone, but in the recurring benefits to our workforce, communities and the planet. The steel we make today can be used again in the future.

The Vagelos Laboratory building illustrates the immense potential of combining American steel with cutting-edge engineering and architecture. It stands as a testament to what is possible when sustainability is a core pillar of design and construction.

For new construction projects, and regardless of one’s alma mater, the choice is clear: American steel is the only sustainable option.

Charles J. Carter is the president of the American Institute of Steel Construction, a nonpartisan, not-for-profit technical institute and trade association established in 1921 to serve the structural steel design community and construction industry in the United States.